Applications

Home / Applications

Ideal laser systems for your sector

Processing with the Cutlite Penta laser systems is successfully applied to a number of sectors as it is rapid, flexible and accurate with no need of any further processing and with minimum production waste.

Find out the application you are interested in and all of the advantages using a laser system.

Industry

The high processing speed and the operating simplicity of the laser machines optimize production times. Laser processing does not require placing and locking the material on the work surface.

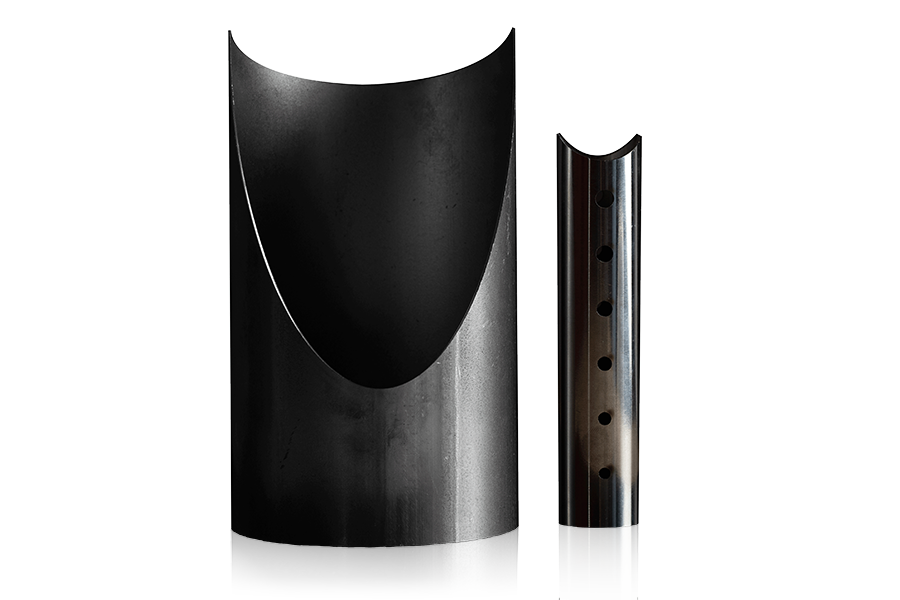

Carpentry

Cutlite Penta offers high-technology solutions for the carpentry sector with fiber laser machines for metal cutting with power up to 50 kW and very high quality processing.

Automotive and household appliances

A large proportion of components in the most common cars and household appliances are manufactured using laser systems, specifically for the benefits they offer in terms of precision and functionality.

Why choose Cutlite Penta?

With our laser systems for material processing you can considerably reduce processing time and costs while having the best cutting quality.

The utmost functionality and usability of the management software make our laser machines’ use intuitive and efficient.

Our technicians develop every machine so as to guarantee the highest level of functionality and customization according to the customer’s needs. Featuring a compact layout as well as the fastest automatic table change in this market, combined with the laser sources power and linear motors our machines can guarantee the highest performance in every component.

In addition to the real advantages offered by our technology we ensure prompt and qualified support so as to rapidly and effectively meet our customers’ needs.

Advantages of Cutlite Penta fiber laser systems on metal:

Fiber laser sources with up to 50 kW power do not require any maintenance

In-house designed and developed cutting head

Gas consumption reduction up to 35 % compared with competitors

Very fast piercing process (<\= 1 sec 20 mm Fe)

Extraordinary cutting quality

Proprietary, user-friendly and intuitive CNC and front-end software

Machine handling by means of linear motors

The fastest automatic table change in the market

Reduced and compact layout

Installation of the machine by the customer in 2 days only

Possible processing of both flat and tubular sheet metal through stand-alone systems (with automatic loaders) or combined machines (sheet plus tube module)