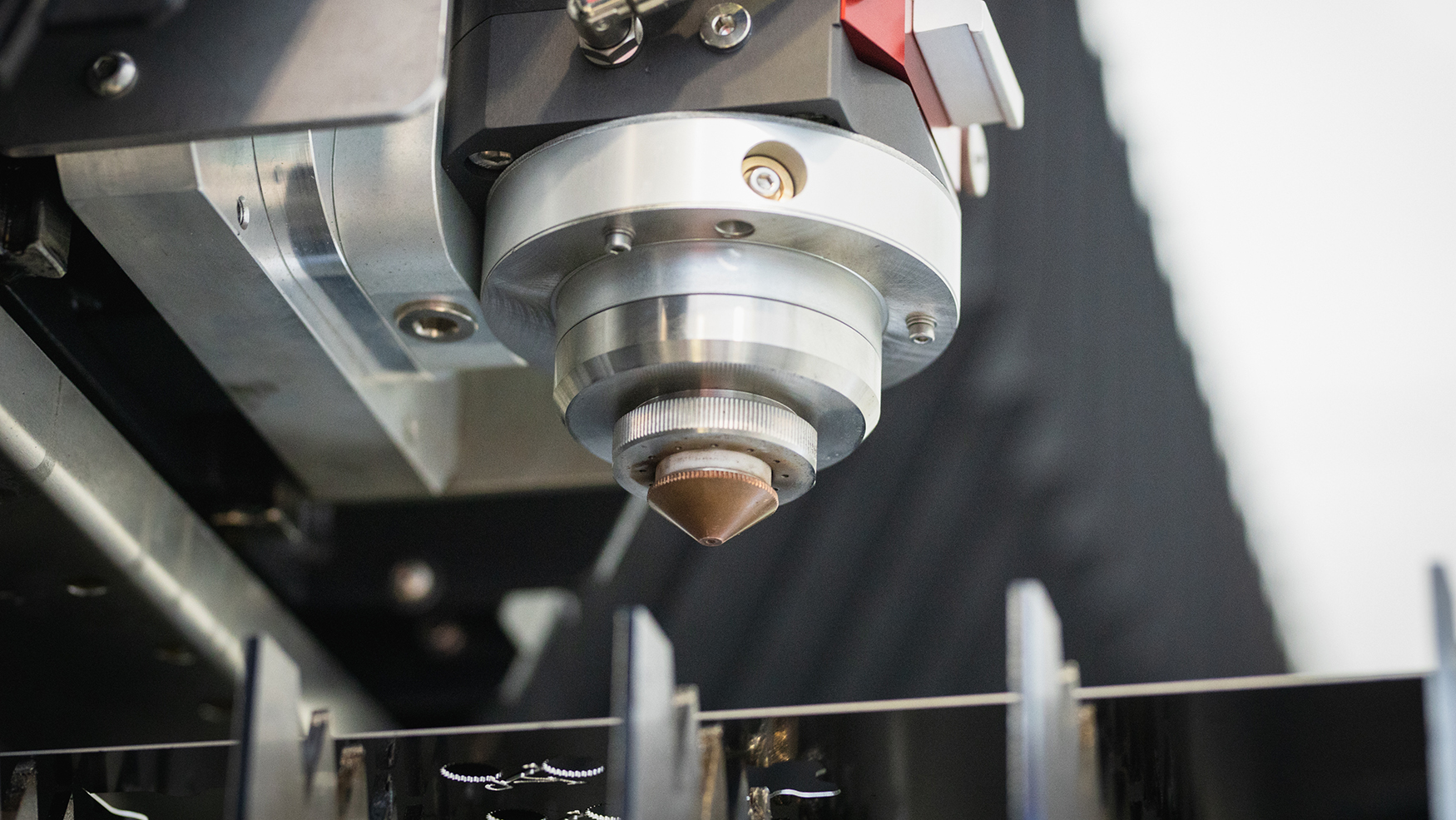

The industrial use of laser cutting machines has grown exponentially in recent years, thanks to the advantages guaranteed by this cutting system. At the same time, the research and development of increasingly high-performance laser systems seeks to meet the constantly growing demand. The result is laser cutting machines capable of withstanding cutting powers previously unattainable. From the 30 kW of fiber laser cutting, introduced for the first time in Italy and Europe by Cutlite Penta, to the new frontier of 40 kW. A goal that has been recently achieved and one that will further extend the use of laser systems in the sheet metal sector, on ever greater thicknesses.

When laser cutting exceeds plasma cutting

Laser cutting and plasma cutting are the two most widely used techniques in the sheet metal industry today. Each of the two cutting systems has specific advantages that have led to a division of the market:

- Plasma cutting, introduced in the 50s, are generally lower-cost systems, although very energy-consuming (they require large amounts of energy to make the cut) and make it possible to cut any type of metal up to about 80mm thick.

- Fiber laser cutting has changed the game. Even more precise and high-performance, they allow cutting on all types of metal thanks to a shorter wavelength that makes absorption in ferrous materials more efficient. With the high powers, fiber lasers are able o cut thicknesses that were previously only the domain of plasma cutting, moreover, the laser is much less energy-intensive than plasma.

Thanks to the fiber laser, the advantages of laser cutting over plasma cutting have become overwhelming, as laser cutting guarantees:

- Very high precision

- Very high speed

- Greater processing versatility

- Process sustainability

- Lower environmental impact (reduced consumption)

- Less material waste during the cutting process, as the beam is much thinner than the plasma so the material lost to cutting is far less.

Very high power laser cutting: what changes?

Research in the field of very high power laser cutting promises to revolutionise sheet metal processing once again. The achievement of a cutting power of up to 40 kW would in fact allow laser cutting to be practised even on thicknesses greater than those currently allowed. A further overcoming of plasma cutting that would allow its replacement in many manufacturing companies.

Greater efficiency and quality, greater respect for the environment

The advantage of replacing plasma cutting systems with laser cutting would be considerable on many fronts. In addition to ensuring better processing quality in extremely short times, laser technology stands out for its processing for the advantages it has for the environment. The use of fiber laser instead of plasma cutting systems would significantly reduce material and electricity consumption, with consequent savings in CO2 emissions. Cutlite Penta is working to achieve such a goal and the threshold of 40 kW is almost a reality.

Discover on the site all the machines for laser cutting of sheet metal.