We have always focused on our customers’ requirements and, thanks to their needs, we have found the grounds for an ongoing improvement and evolution of our products. That is the case of our cutting heads too.

Our Service Department has a special focus on the inputs from our customers and is able to create customized solutions, providing ongoing support.

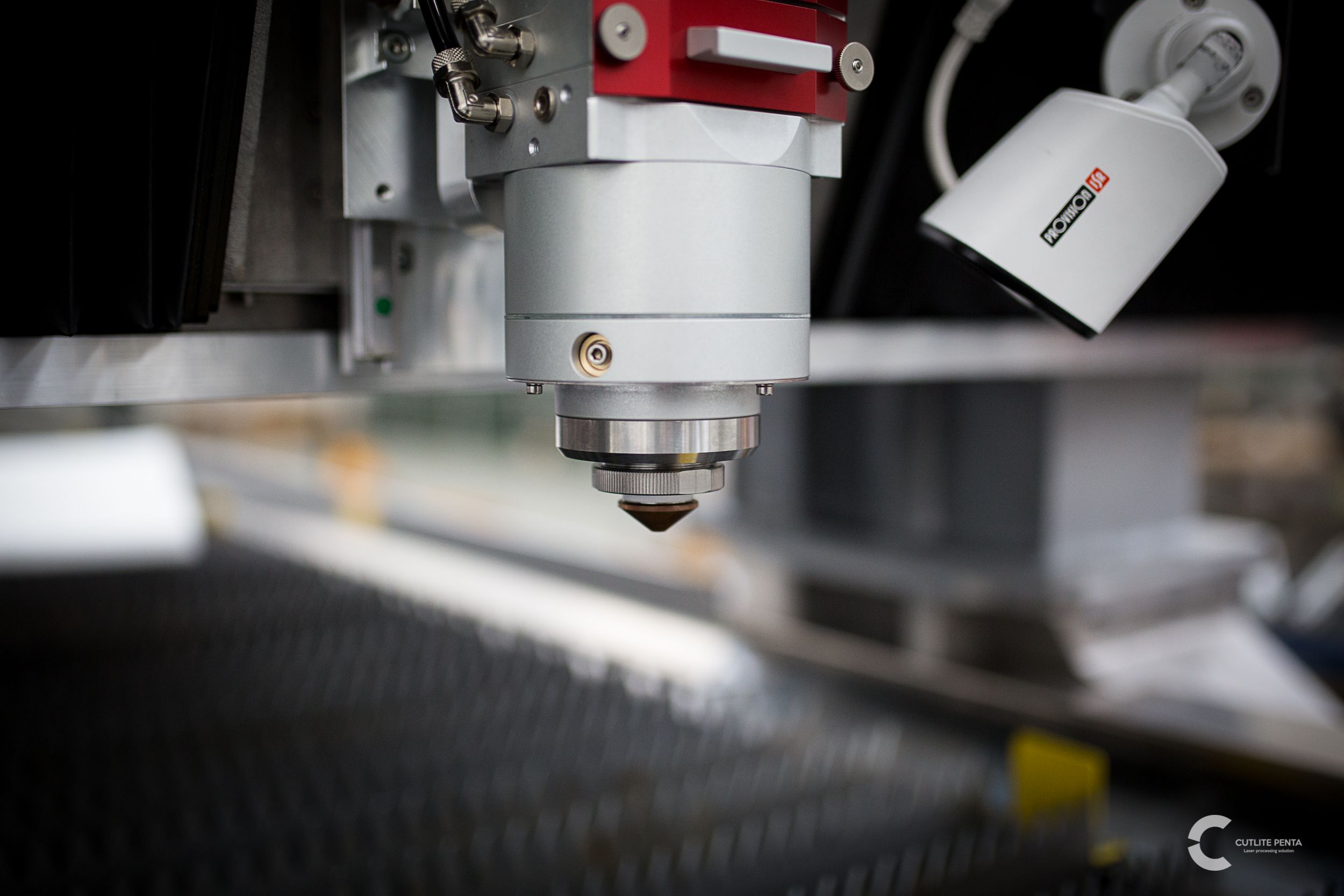

An example of product developed according to the specific requirements of some customers is our FIBER cutting head for medium-high power Fiber laser.

The very first Fiber head version, that is currently installed on our LME Fiber laser cutting systems, has always been outstanding for its very high quality cutting of a number of metals coupled with advanced and customized nozzles.

We have installed over 300 heads in this model, with a number of customizations of collimator/focal, based on the customers’ laser powers and requirements.

The limit we have overcome is associated with the beams’ power: in fact, the Fiber head could not feature beams over 6KW.

The evolution of our cutting head

Studies on and the development of the Fiber head led to the realization of the new ‘EVO 1’ cutting head we presented at Fiera Lamiera 2017, with a 8KW laser source. The EVO 1 head was studied and designed with optics suitable for high powers that our laser systems required.

The EVO head design was further developed to finally lead to the realization of our top model: the Evo 2 Fiber head. This model, completely sensor-driven, has considerably improved the cut of very high thicknesses, from steel to carbon (over 25mm). Furthermore, it has allowed cutting very-high-thickness stainless steel (25/30mm) with laser power from 8KW up to 12KW; this is the result of tests carried out in Research and Development at much lower pressures of N2 (nitrogen), due to the study on the head fluid dynamics (example: stainless steel cut of 20mm with 8KW with only 14 BAR of N2). This allows considerable saving in terms of cutting gas, guaranteeing the cutting qualities at the same time.

The EVO 2 head is a further evolution in terms of weight, dimensions and performance and the customers’ feedbacks have been very positive.

And more: we are also testing the head on 5-axis machines with high powers (over 12KW).

An additional strength and point of reference for our customers is the Service Department as, producing and testing all components of our heads in-house, it is always ready to meet any requirements and face any eventuality.