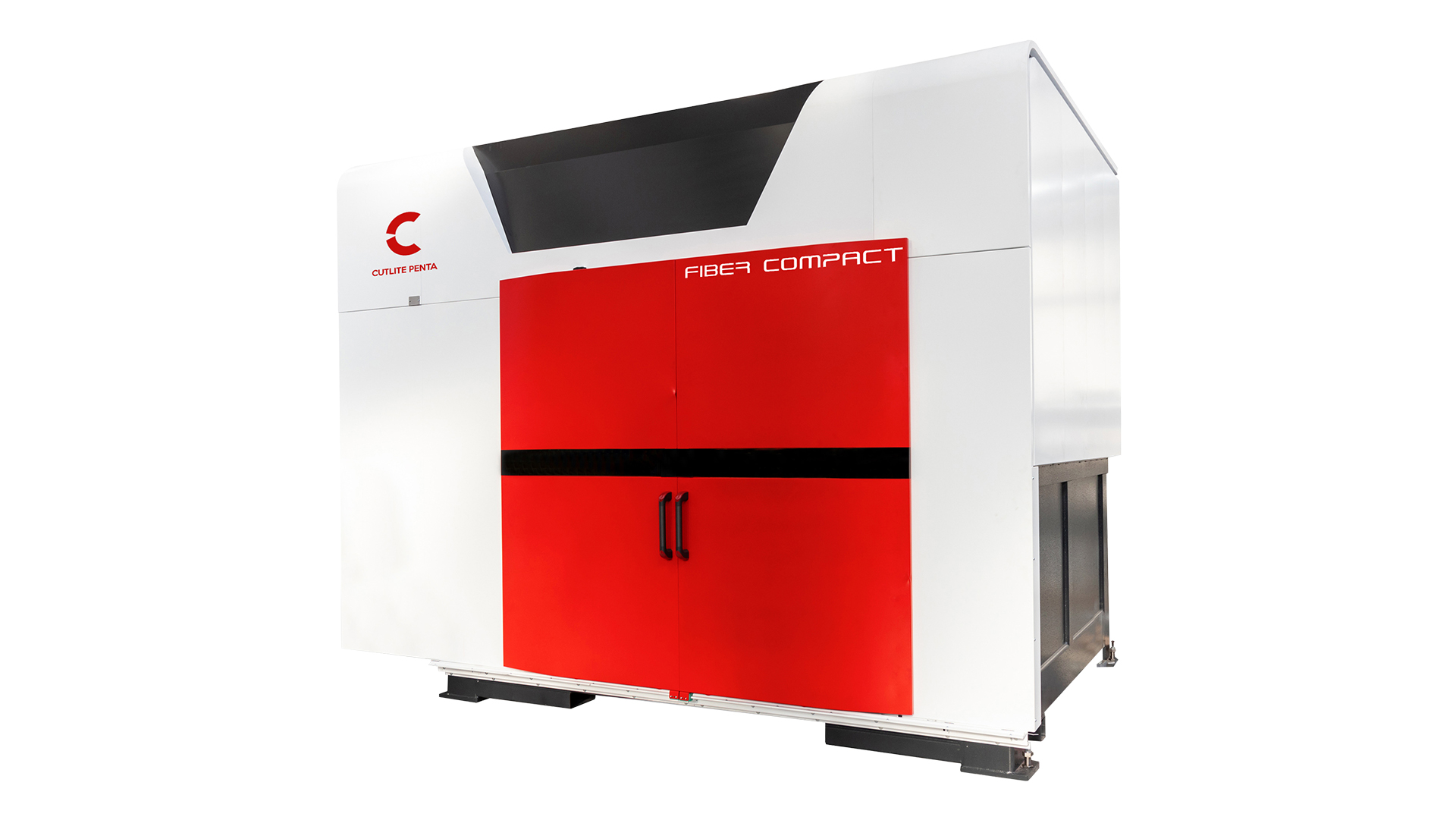

Fiber Compact

High precision of cutting

Power up to

50 kW

WORKING AREA UP TO

4000×2000 mm

The machine for 3D cutting

Its fiber laser source allows treating metals. Therefore, its natural application is within the precision mechanical engineering industry. Linear motors allow rapidly reaching the most difficult corners of the piece to be treated.

This way, the part is fixed and cutting accuracy is guaranteed. The machine is controlled by the Alfa Learning device, a control and self-learning software easy to be used. Alfa Learning allows entering data on an 8′ portable tablet.

configurator

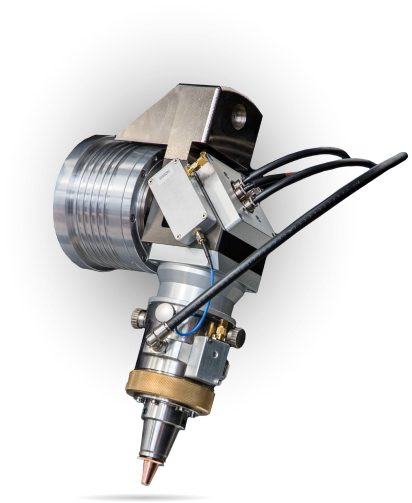

Five axes head

Five axes head is available and allows caulking and bevel cutting operations on profiles thus completing the manufacturing process. The (B, C) rotary axes motors are hollow and absolute, there is no longer gearing transmitting motion but transmission is now direct and more accurate with no tooling needs in case of shock thus guaranteeing excellent dynamics.

Laser Sources

Fiber laser sources provide extensive versatility and make it possible to cut a multiplicity of metal types. Developed as a single system, it can be paired with a wide variety of optical fiber diameters. High efficiency, excellent beam quality and low power consumption are all hallmarks of the source.

The source is housed in a NEMA 12 cabinet which is conditioned and sealed so that it can operate even in the harshest of environments. The high degree of reliability of these sources also ensures particularly low maintenance costs.

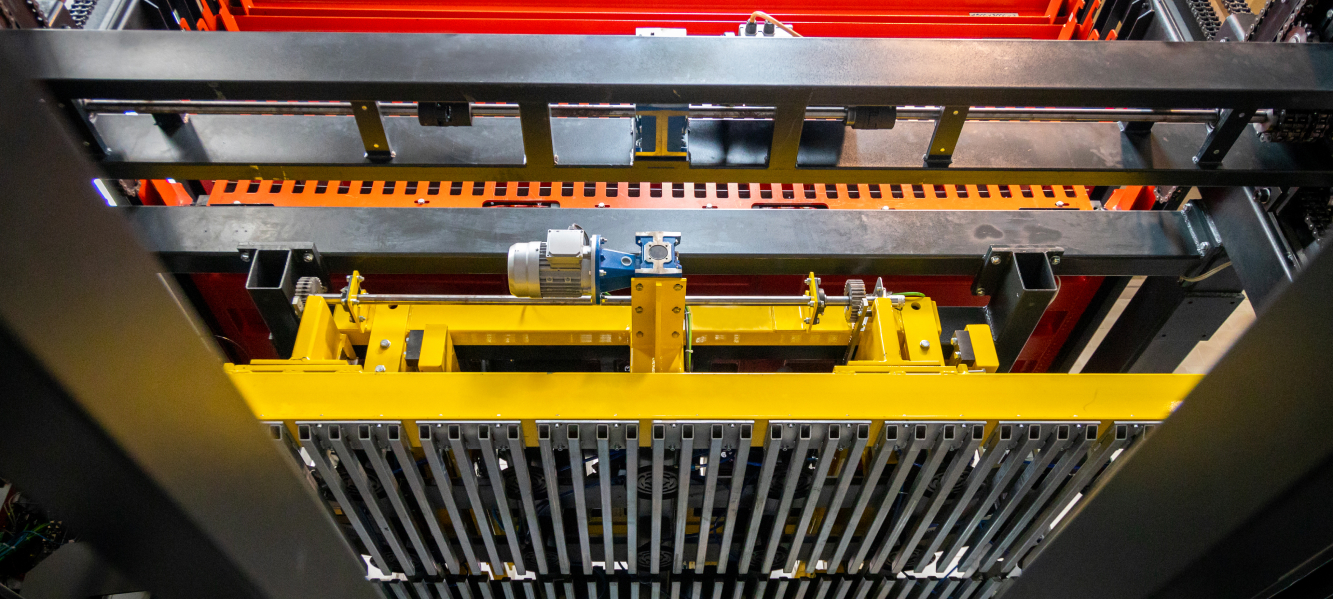

Mechanical design

The base is an electro-welded steel frame which is then machined to

accommodate the absolute high-precision guides and linear motors.

The gantry frame is made up of a light, sturdy steel beam that is stiff enough to compensate for thermal expansion with no deformation.

This type of configuration provides remarkable dynamic performance.

Electro-welded steel structure

High dynamic performance

Thermal expansion without deformation

Loading/unloading and Warehouses

Cutlite Penta also produces in-house in-line or 90° loading and unloading systems combined with vertical storage warehouses that communicate directly with our laser systems.

hardware solutions

Camera

A position camera that enables remote monitoring and viewing of machine operation.

Automation

This option allows optimisation of processing times, almost entirely masking loading and unloading times.

Software

Simple and intuitive cutting-edge front-end software, designed to guarantee the highest level of versatility and customisation. Laser cutting has never been so easy.

Smart Manager Plus

An innovative software for machine management and supervision. With Internet access, the system can be monitored via remote assistance using TeamViewer.

Smart Composer

Cutlite Penta’s revolutionary new software interfaces seamlessly with the machine’s numerical control and smart manager front-end software.

samples

Technical Features

| MODEL | 2D WORKING AREA | 3D WORKING AREA |

| 1515 | 1500 x 1500 mm | 1000 x 1000 mm |

| 2015 | 2000 x 1500 mm | 1500 x 1000 mm |

| 3015 | 3000 x 1500 mm | 2500 x 1000 mm |

| 4020 | 4000 x 2000 mm | 3500 x 1500 mm |

| Z-AXIS | SPEED |

| 720 mm / 980 mm /1200 mm /1600 mm | Up to 100m/min |

| LASER POWER |

| 1000 W |

| 1500 W |

| 2000 W |

| 3000 W |

| 4000 W |

| 6000 W |

| 8000 W |

| 10000 W |

| 12000 W |

| 15000 W |

| 20000 W |

| 30000 W |

| 40000 W |

| 50000 W |

Choose the Cutlite Penta laser solution that best meets your business requirements

Our team of experts is ready to help you and show the most suitable solution for your needs.

How can we help you:

- Analysis

- Consultation

- Solution proposal

- Quote

- Support