Technological evolution has brought about considerable changes in the metal cutting industry, in particular with the introduction of fibre lasers. In this interview, we have the pleasure of talking with LaserJet, a company that has established itself as a leader in the sector also thanks to the use of Cutlite Penta laser systems. This is how the technology of Cutlite machines has revolutionised their business and what are the future prospects.

Hello, could you tell us briefly about the history of LaserJet and how you started working with lasers?

Initially, our family was linked to agriculture, but then we decided to take a new path by opening a company specialising in cutting, bending and welding for third parties. We focused on the production of gym machines, but later we discovered the potential of laser cutting. We were among the first pioneers in the use of lasers for industrial cutting and over the years the company has grown to become three different companies: LaserJet, which produces machines for mowing grass; a company specialising in carpentry; and a group that deals with various industrial activities.

What services does LaserJet offer and in which sectors does it operate?

We offer services on behalf of third parties in various sectors, including agriculture, oenology and the production of metal structures. Our customers ask us to cut, fold and weld products such as telescopic booms for vans and turrets in Geneva. We are always looking for innovative solutions and cutting-edge technologies, just like the laser we use for cutting.

How did you discover Cutlite Penta and why did you decide to invest in its laser machines?

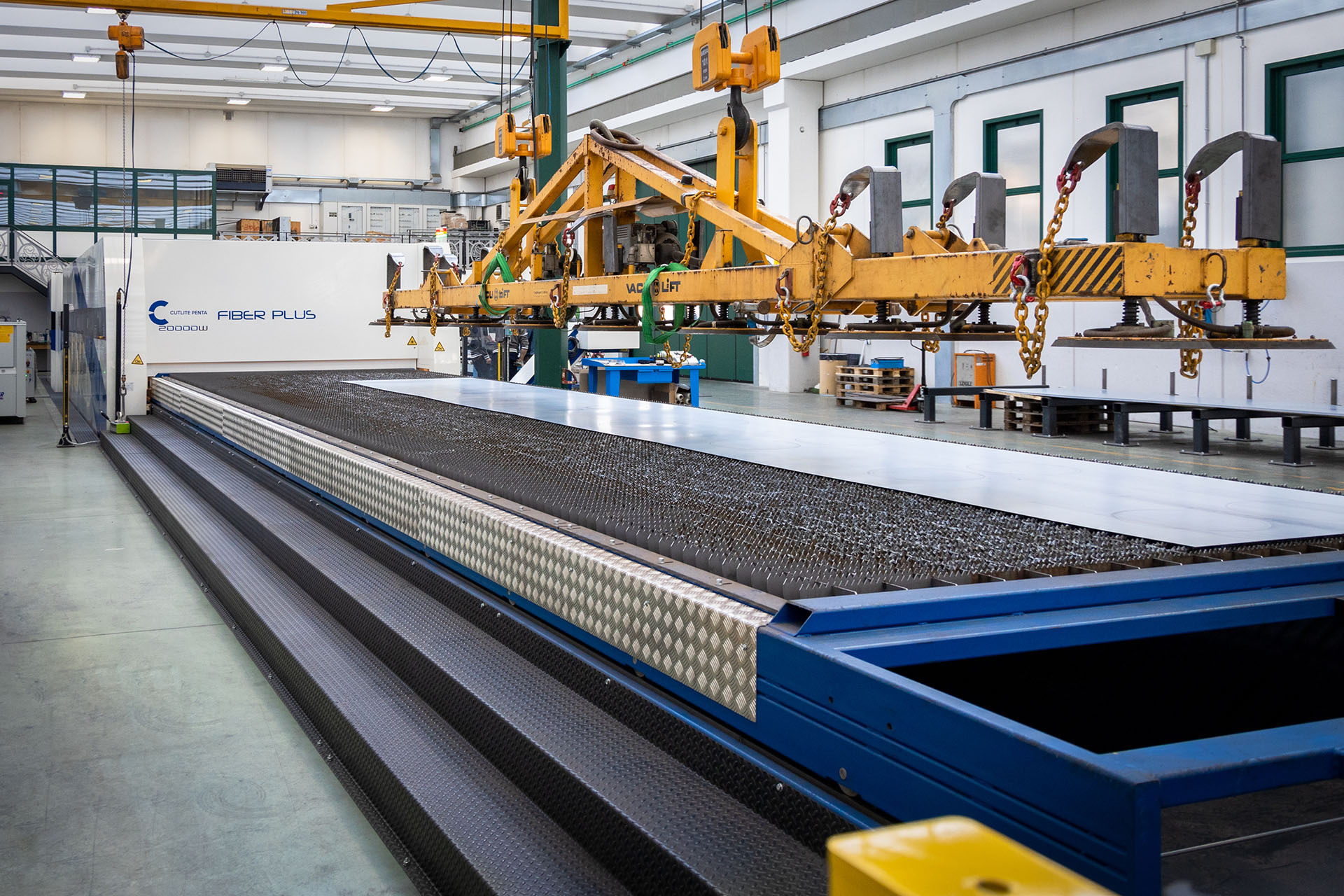

We were looking for a laser system to replace our old model, the Bytronic, for over five years. We have considered several options, including competition, without success. We couldn’t find anything interesting on the market. Our previous machine was no longer able to met our needs. We had the opportunity to meet Cutlite Penta, who showed us the cutting capabilities of its machine, and we were impressed. We therefore decided to buy it, because it met our requirements for cutting different materials such as iron, steel, aluminium, etc. Cutlite Penta proved to be superior to other competitors on the market.

How did you find the Cutlite Penta laser machine?

We experienced some challenges during the installation of the machine, but now that it is working, we are satisfied with its performance. Laser technology has revolutionised the cutting industry, enabling more precise and high-quality machining. We can cut tough materials with ease. We are continuously updating our skills to remain competitive in a constantly evolving market. The use of light and resistant materials has become increasingly common, which requires the adaptation of our machines.

Have you tried new cutting methods or innovative technologies with Cutlite Penta?

We tested the mixed cut with Cutlite Penta and found the perfect configuration for our needs. We have improved the gas mixture for optimal results. For example, we found that a mixture of nitrogen and oxygen at 98% and 2% respectively worked very well. However, stability of the mixture is essential. Even a small variation in gas composition can affect cutting, creating slag or leaving the cut material with a poor finish. Therefore, maintaining a stable gas composition during the cutting process is of utmost importance.

We have faced some challenges in trying to adopt technologies already tested by Chinese manufacturers. Initially, we were planning to import a compressor generator set from them, but we ran into issues with certificates and regulations. Eventually, we found a solution here in Italy and installed an iron cutting plant with the right gas mixture.

Cutlite Penta has allowed us to expand our working range, covering cuts from one millimetre up to 200 millimetres thick. We are trying to diversify our business and continuously improve. The future will see us grow as a company and transfer new knowledge to other machines. The laser cutting industry is constantly evolving thanks to technological innovations, and we try to keep up with these innovations.

In your cutting industry, you have noticed changes over the years. Could you tell us about these changes and the challenges you have faced?

Over the years, we have seen significant changes in our cutting industry. The introduction of lasers has revolutionised the way we work on sheet metal and metal sheets. The cutting precision achieved thanks to the laser was a real leap in quality compared to ten years ago. This precision allows us to obtain high quality machining and, in many cases, it is no longer necessary to resort to additional mechanical machining.

Furthermore, we started working with high-strength materials to reduce the weight of the structures. These lightweight yet strong materials require specific skills to be processed properly. For example, to bend them without creating cracks, a considerable amount of pressure and the appropriate wire is required. Welding is an essential element in our work, especially because many of our creations are used by people who work several metres high for many hours. Therefore, it is essential to ensure strong and high quality welds.

To stay competitive in the market, we need to stay constantly updated on new technologies and understand which solution is the best one to improve performance. Flexibility, speed and precision are key to staying competitive and gaining new skills.

Our industry is undergoing constant change and we need to adapt quickly. Improved technologies and the use of advanced materials allow us to offer more precise and high quality processes to our customers.

What are your future goals as a company in the cutting industry?

Our goal is to continue to grow, improving what we have and looking for new opportunities for expansion. In the cutting industry, we have noticed changes over the years and are ready to adapt to new technologies and customer needs. We wish to remain competitive and offer increasingly precise and high quality workmanship. Cutlite Penta was a breakthrough for our company in the laser cutting industry. Its advanced technology and top-notch performance have allowed us to improve the quality of our products and remain competitive in the market. We are excited to continue to grow and adopt new solutions to meet the needs of our customers.

Learn more about Cutlite Penta laser systems or contact us for information.