Automation

Automation Systems to simplify every operation

Cutlite Penta laser systems are equipped with advanced automation systems to simplify operational processes, reduce downtime, and increase company productivity. From loading and unloading systems to direct connections with automated warehouses, they save time and resources in every operation.

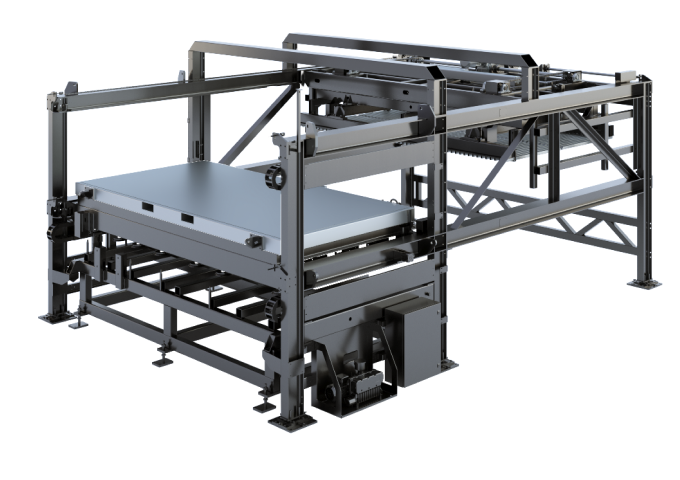

Automatic loading and unloading system

Our automatic loading and unloading system optimizes the entire sheet metal handling process, improving efficiency and safety through:

- Vacuum lifter mounted on a mobile carriage, transferring the material from the loading station to the laser table. Equipped with two electric axes with feedback from absolute encoders, it automatically handles gripping, unloading, and thickness control of the sheet with vertical movement. Featuring air blasts and metal brushes, it ensures clean and precise handling.

- Forklift with a wide vertical stroke, positioned above the external table of the laser cutting machine. The forks, controlled by two axes with absolute encoders, lift and place the already cut material onto the laser table. A third motor allows the entire system to be moved out of the operating area, keeping the work zone clear and safe during manual loading. Upon request, the forks can be coated with scratch-resistant material to protect delicate surfaces.

- The structure of the loading and unloading system is positioned above the laser’s pallet changer, with installation at a 90° angle or inline, depending on the required configuration.

Automatic storage warehouses

With our automated warehouses, designed to maximize production efficiency, material management is simpler and optimized. Both DCS and DFS systems are controlled by supervisory software with a simple and intuitive operator interface, which manages quantities and material database to better control the available stocks. Both the loading/unloading device and the automatic warehouse are equipped with all necessary active and passive safety systems.

Dynamic Compact Storage – DCS

DCS is a high-efficiency vertical storage system, with a variable number of drawers tailored to production needs.

- Perfect integration: the system is positioned above the pallet changer, optimizing space without increasing the footprint.

- Highly dynamic handling: the drawers are operated by a fast and precise shuttle, guaranteeing a continuous workflow.

- Operational versatility: the system contains loading units for both sheets to be processed and those already cut, improving the organization of the production process.

Dynamic Compact Storage – DCS

The automatic loading and unloading system DFS can be connected to an automatic storage warehouse to ensure greater autonomy and optimize cutting schedules.

- Customized design: the warehouse is built according to specific production requirements and available space, with a number of loading units defined by the height of the installation area.

- Flexible storage: allows both the storage of sheet metal to be processed and the placement of cut material in removable cradles, equipped with access points for the forklift.

- Expandability: the ability to integrate one or more storage towers to increase operational capacity.

Contact us

Request information about the available automation options for your new laser system.